We are Channel Partner of KOEL Ltd. for the sale of Silent Kirloskar Green Make D G Sets through their OEM network in Chandigarh, Haryana, Himacahal Pradesh, J&K and Punjab

We are Channel Partner of KOEL Ltd. for the sale of Silent Kirloskar Green Make D G Sets through their OEM network in Chandigarh, Haryana, Himacahal Pradesh, J&K and Punjab

Diesel Generating Set

Diesel Generator Petrol Generator

Diesel Engine

Pums

Diesel Engine Pumping Sets

Air Cooled Pumpung Sets Water Cooled Pumpung Sets

Industrial Pumps

End Suction Pumps Process Pumps Multistage Pumps Horizontal Splitcase Pumps Fire, V.T. & Special Pumps Valves

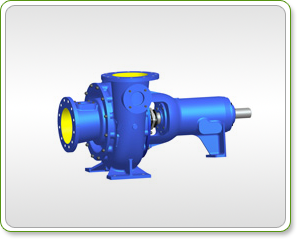

With a back pull out design these pumps are gland packed or mechanically sealed and are used for air conditioning, booster service, fire fighting and sprinkler system. Delivery size varies from 32 mm to 150 mm.

These pumps are used for irrigation and water supply application. They are supplied with direct/pulley drive and are electric motor driven or engine driven. Delivery size varies from 50 mm to 150 mm with a power rating of 2.2 kw to 18.33 kw.

These pumps can be driven by electric motor or engine. The impellers are of enclosed type and are balanced statically and dynamically. The casing has axial suction and top centre line delivery. Smooth hydraulic passages ensure high efficiency.

These low head high capacity pumps can be either gland packed or mechanically sealed. Delivery options can be of either horizontal or vertical. These are majorly used in air conditioning, irrigation, drainage and storm water. Delivery size can vary from 200 mm to 650 mm.

These pumps are of single stage with back pull out type suitable for 3500 rpm. These are either gland packed or mechanically sealed and delivery size can be up to 125 mm. These are very useful in air conditioning, water supply, fire-fighting and booster services.

SHM are horizontal non-clog pumps having single stage, single suction with back pull out type design. SHS are vertical non-clog pumps for wet pit applications. The pump section is suspended by a column pipe which also protects the transmission shaft. These pumps can be offered with a column length up to 6.5 m. The impeller is single suction type non-clog, free flow dynamically balanced. For SHM pumps the standard lubrication is grease and the optional one is oil. In case of SHS pumps the lubrication is grease based. These pumps are widely used in paper industries, water carrying gravel and so on.

SHM are horizontal non-clog pumps having single stage, single suction with back pull out type design. SHS are vertical non-clog pumps for wet pit applications. The pump section is suspended by a column pipe which also protects the transmission shaft. These pumps can be offered with a column length up to 6.5 m. The impeller is single suction type non-clog, free flow dynamically balanced. For SHM pumps the standard lubrication is grease and the optional one is oil. In case of SHS pumps the lubrication is grease based. These pumps are widely used in paper industries, water carrying gravel and so on.

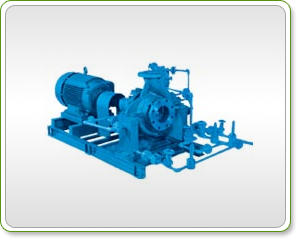

These pumps are developed for process applications and are generally conforming to API 610. These are gland packed or mechanically sealed. These pumps are ideal for air conditioning, condensate extraction, distilleries, edible oil sugar and textile. Delivery size ranges from 20 mm to 200 mm.

These pumps are developed for process applications and are generally conforming to API 610. These are gland packed or mechanically sealed. These pumps are ideal for air conditioning, condensate extraction, distilleries, edible oil sugar and textile. Delivery size ranges from 20 mm to 200 mm.

i-CP pumps dimensionally conform ISO:2858. These pumps are horizontal, radially-split, single stage, centrifugal end suction volute with top centreline delivery. The pump feet are integrally cast with the delivery casing. The impeller is of enclosed type. The pump shaft is supported by pre-lubricated anti friction sealed bearings as a standard scope of supply. These are widely used in Chemical industries, food and beverages industries, off sites of petro chemicals and refineries.

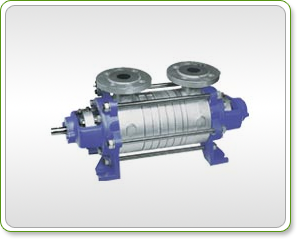

RKB is a multistage centrifugal side suction, vertical delivery, horizontal pump with diffuser type casing. Pump shaft is supported in anti-friction bearings. Enclosed impellers are of radial flow type provided with balancing holes. These pumps have standard lubrication of grease and are suitable for coupling with electric motors.

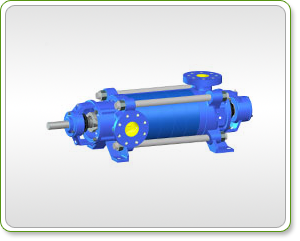

These are single suction, horizontal shaft, high pressure multistage pumps, consisting of ring section diffuser casings bolted between suction and delivery casing with enclosed type impeller. These are ideal for sprinkler irrigation, fire-fighting, water supply in high rise buildings and so on.

These pumps are of multistage and have a modular construction. These are either gland packed or mechanically sealed and can be of either electrical drive or engine drive. These are widely used in air conditioning, boiler feed, petroleum, chemical and process industries and so on.

Kirloskar KSIL, KCIL are vertical multistage centrifugal pumps. The in-line design enables installation of the pump in horizontal one pipe systems. The suction and discharge ports are of same dimension and are in the same horizontal plane. This arrangement insures a compact design and calls for a simpler piping systems.

These pumps are gland packed and have mechanical seal. These are mainly used in water supply, irrigation, power plants and can have delivery size up to 1100 mm.

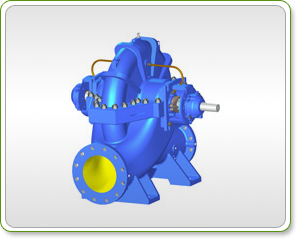

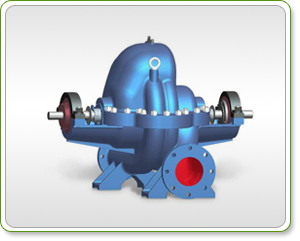

These are horizontally axially split casing, single stage, double suction or single suction pumps with horizontal shaft and detachable stuffing box called insert with horizontal axially split volute type. The impeller is accurately balanced by double or single suction. These pumps are used in handling water with slight impurities, petroleum refineries, conditioning and refrigeration system and so on.

These pumps are horizontally mounted having axially split casing. They can either be single stage or double stage. These are designed with single suction with a single volute operating at 50 Hz or 60 Hz. These pumps are used in urban water supply, industries, irrigation, air conditioning and so on.

iHT pumps are horizontal split case single/double stage centrifugal pumps. All single stage pumps are provided with double suction type impeller. Both single stage/double stage pumps are fitted with DIN 24960 cavity mechanical seal. The impeller/s is/are centrally placed on a sturdy designed shaft and the entire rotating assembly is dynamically balanced to provide a smooth, trouble free, longer and efficient operation.

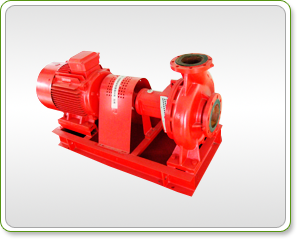

Kirloskar Brothers Limited has been supplying Fire Protection Packages for many decades. The most important aspect of Fire Protection package is the reliability of the fire fighting pumping system to ensure adequate water supply at required pressure at emergency conditions.

Theses pumps are constructed rigidly to ensure vibration free operation. Hydraulic design is being updated with our continuous R&D efforts to meet requirements of higher efficiency and lower submergence, taking care of other parameters such as, high reliability and optimum system design.

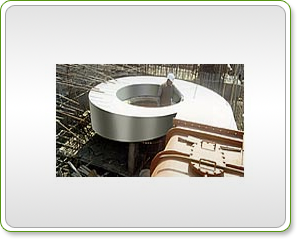

These pumps are called Concrete Volute Pumps (CVP) because the casing and suction draft tube is cast in-situ concrete with rotating metallic part. These pumps comprise concrete volute casing, draft tube, grouted embedded, components and rotating assembly. These pumps find applications where large quantity of flow is required to be handled, most suitable for sea water application. Some of the advantages of KBL manufactured CVPs are high reliability, design simplicity, superior operating performance, vibration free equipment and low maintenance cost.

Canned Motor Pump is a centrifugal pump with hermetically sealed electric motor mounted on single shaft thus eliminating the requirement of mechanical seal or other sealing device. Entire rotating assembly is immersed in the liquid, and motor stator and rotor are isolated from the pumped liquid with corrosion resistant, non-magnetic liner and sleeve. A part of the pumped liquid is by-passed through the motor, for cooling of motor and lubricating the bearing.

These are single stage, single suction pumps with overhung non-clogging impeller. Pumps can be offered in stationary as well as transportable arrangements. The stationary arrangement is supplied with pump connector unit and the connector unit is connected to pump support bracket with rubber diaphragm to make it leak proof joint.